7.3 Exhaust Back Pressure Sensor Symptoms; Must Read

A malfunctioning 7.3 Exhaust Back Pressure Sensor (EBPS) can result in reduced engine power, hesitation during acceleration, rough idling, a check engine light, and black exhaust smoke. These symptoms indicate the need for EBPS inspection and potential replacement to maintain engine efficiency.

Discovering potential issues with your 7.3 Exhaust Back Pressure Sensor (EBPS) is crucial for maintaining your diesel engine’s performance. In this article, we’ll outline the telltale symptoms of a malfunctioning EBPS that every Power Stroke owner should be aware of. Understanding these signs can help you diagnose and address problems early, ensuring your engine runs smoothly.

Table of Contents

- What does the back exhaust back pressure sensor do in a 7.3?

- What are 7.3 Exhaust Back Pressure Sensor Symptoms?

- How to fix 7.3 EBP sensor problems?

- What is the 7.3 exhaust back pressure sensor delete procedure?

What does the back exhaust back pressure sensor do in a 7.3?

In a 7.3L Power Stroke diesel engine, the Exhaust Back Pressure Sensor (EBPS) plays a crucial role in monitoring and regulating the exhaust gas pressure. Specifically, its primary functions include:

- Monitoring Exhaust Gas Pressure: The EBPS constantly measures the pressure of the exhaust gases as they exit the engine’s cylinders and enter the exhaust system.

- Providing Feedback to the PCM: The data collected by the EBPS is transmitted to the Powertrain Control Module (PCM), also known as the engine control module. The PCM uses this information to optimize engine performance and emissions by adjusting various parameters, such as fuel injection timing and turbocharger operation.

- Preventing Overboost: One of the critical roles of the EBPS is to prevent overboost conditions in the turbocharger system. If exhaust pressure becomes too high, it can lead to excessive turbocharger boost, potentially causing engine damage. The EBPS helps the PCM regulate the turbocharger’s wastegate, ensuring that the boost pressure remains within safe limits.

In summary, the Exhaust Back Pressure Sensor in a 7.3L Power Stroke engine monitors exhaust gas pressure and provides essential data to the PCM, allowing for precise control of engine performance, emissions, and turbocharger operation to ensure safe and efficient engine operation.

What are 7.3 EBP sensor readings?

The normal exhaust back pressure sensor (EBPS) reading for a 7.3L Power Stroke engine is between 0 and 1 psi. If the EBPS reading is higher than 1 psi, it could be a sign of a problem with the engine, such as a clogged exhaust system or a faulty turbocharger.

Here are some possible causes of high EBPS readings:

- Clogged exhaust system: If the exhaust system is clogged, it will restrict exhaust gas flow, which can cause the EBPS reading to increase.

- Faulty turbocharger: The turbocharger helps to reduce the amount of exhaust back pressure. If the turbocharger is not working properly, it can cause the EBPS reading to increase.

- Faulty EGR valve: The EGR valve recirculates exhaust gas back into the intake manifold. If the EGR valve is not working properly, it can cause the EBPS reading to increase.

- Faulty EBPS sensor: It is also possible that the EBPS sensor itself is faulty. If this is the case, the sensor will need to be replaced.

If you are experiencing high EBPS readings, having your engine diagnosed by a qualified mechanic is important. A mechanic can use a scan tool to check the data from the EBPS sensor and other sensors to determine the cause of the problem.

What are 7.3 Exhaust Back Pressure Sensor Symptoms?

The Exhaust Back Pressure Sensor (EBPS) in a 7.3L Power Stroke engine can develop issues over time, and these problems often manifest in several noticeable symptoms. Here are the common symptoms of a faulty EBPS, explained in detail:

1. Reduced Engine Power

A faulty EBPS can result in reduced engine power and performance. The sensor’s failure to accurately measure exhaust back pressure may cause the engine to enter a “safe mode” where it limits power output to prevent potential damage.

When the EBPS fails, it may send incorrect data to the PCM. In response, the PCM may restrict fuel injection and turbocharger operation to protect the engine from overboosting or other potential issues.

2. Hesitation During Acceleration

Drivers may experience hesitation or delayed response when accelerating from a stop or during overtaking maneuvers.

The EBPS helps control fuel injection timing, and inaccurate sensor readings can lead to incorrect fuel delivery, causing hesitation or sluggish acceleration.

3. Rough Engine Idle

A faulty EBPS can result in an irregular or rough engine idle, characterized by uneven engine revving or shaking.

The EBPS contributes to regulating the air-fuel mixture, and when it malfunctions, it can disrupt this mixture, leading to unstable idling.

4. Check Engine Light (CEL)

A malfunctioning EBPS often triggers the illumination of the Check Engine Light on the instrument panel.

When the PCM detects inconsistent or out-of-range signals from the EBPS, it generates a diagnostic trouble code (DTC) and turns on the Check Engine Light to alert the driver to a potential problem.

5. Black Smoke from the Exhaust

A faulty EBPS can cause the engine to run rich, producing excessive black smoke from the exhaust pipe.The sensor’s inability to accurately measure exhaust back pressure can lead to incorrect fuel injection timing, causing an overly rich air-fuel mixture and black smoke emissions.

6. Poor Fuel Efficiency

Drivers may notice a decrease in fuel efficiency, with the vehicle consuming more fuel than usual. A malfunctioning EBPS can lead to suboptimal engine performance and fuel management, resulting in higher fuel consumption.

It’s essential to address these symptoms promptly by diagnosing and replacing a faulty EBPS to restore proper engine performance, fuel efficiency, and emissions control. If you encounter these symptoms in your 7.3L Power Stroke engine, consult a qualified mechanic to perform the necessary diagnostic tests and repairs to ensure the sensor functions correctly.

Can A Bad Downstream Oxygen Sensor Cause A Rough Idle?

sensor diary

How to fix 7.3 EBP sensor problems?

Fixing Exhaust Back Pressure Sensor (EBP) problems in a 7.3L Power Stroke engine typically involves diagnosis, replacement of the sensor if necessary, and ensuring that the underlying issues causing the problem are addressed. Here’s a step-by-step guide on how to fix EBP sensor problems:

1. Diagnostic Steps

- Check for Error Codes: Start by using an OBD-II scan tool to retrieve any diagnostic trouble codes (DTCs) related to the EBP sensor. These codes can provide valuable information about the issue.

- Visual Inspection: Visually inspect the EBP sensor and its wiring for any signs of damage, corrosion, or loose connections. Ensure that the sensor is securely attached to the exhaust manifold.

- Test the Sensor: Use a multimeter to check the electrical resistance of the EBP sensor. Consult the vehicle’s service manual for the specific resistance values expected at different temperatures. Compare your readings to these values to determine if the sensor is within the specified range.

2. Replacement of the EBP Sensor

- Safety Precautions: Ensure that the engine is cool before starting the replacement process to avoid burns. Disconnect the vehicle’s battery to prevent electrical hazards.

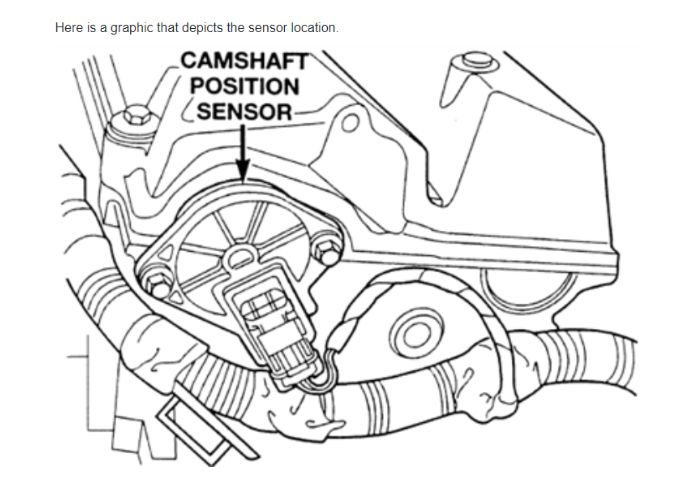

- Locate the EBP Sensor: The sensor is typically located on the exhaust manifold. Refer to the vehicle’s service manual to pinpoint its exact location.

- Disconnect Wiring: Carefully disconnect the electrical connector from the EBP sensor.

- Remove the Old Sensor: Use an appropriate socket or wrench to remove the old EBP sensor from the exhaust manifold. Take care not to damage the threads or surrounding components.

- Prepare the New Sensor: Apply a thin layer of high-temperature gasket sealant to the threads of the new EBP sensor. This helps ensure a proper seal and prevents exhaust gas leaks.

- Install the New Sensor: Thread the new EBP sensor into the exhaust manifold by hand, then tighten it to the manufacturer’s recommended torque specification using a torque wrench.

- Reconnect Wiring: Reconnect the electrical connector to the new EBP sensor.

3. Clear Error Codes and Test

- Clear DTCs: Use the OBD-II scan tool to clear any diagnostic trouble codes stored in the PCM related to the EBP sensor issue.

- Test Drive: Take the vehicle for a test drive to ensure that the symptoms of the EBP sensor problem have been resolved. Monitor engine performance and look for any recurrence of the symptoms.

4. Address Underlying Issues

If the EBP sensor problem was caused by other issues, such as clogged exhaust passages, damaged wiring, or issues with the PCM, address these underlying problems to prevent future sensor failures.

Regularly perform maintenance on the vehicle, such as cleaning the EBP sensor connector and inspecting the wiring harness for damage.

It’s important to note that if you are not comfortable or experienced with vehicle repairs, it’s advisable to seek the assistance of a qualified mechanic or technician to diagnose and fix EBP sensor problems. Additionally, always refer to the vehicle’s service manual for specific procedures and torque specifications related to your particular make and model.

ICP Sensor 6.0 Powerstroke Symptoms; Well Explained

Sensor diary

What is the 7.3 exhaust back pressure sensor delete procedure?

Performing an Exhaust Back Pressure Sensor (EBP) delete on a 7.3L Power Stroke engine typically involves physically removing and replacing the EBP sensor with a threaded plug or an EBP sensor delete kit.

The specific steps may vary depending on the kit used. After the delete, the vehicle’s Engine Control Module (ECM) or Powertrain Control Module (PCM) may need to be reprogrammed or tuned to accommodate the EBP sensor removal and prevent error codes.

Keep in mind that EBP sensor deletes are often performed for performance or aftermarket modifications and may not be legal in all regions due to emissions regulations.