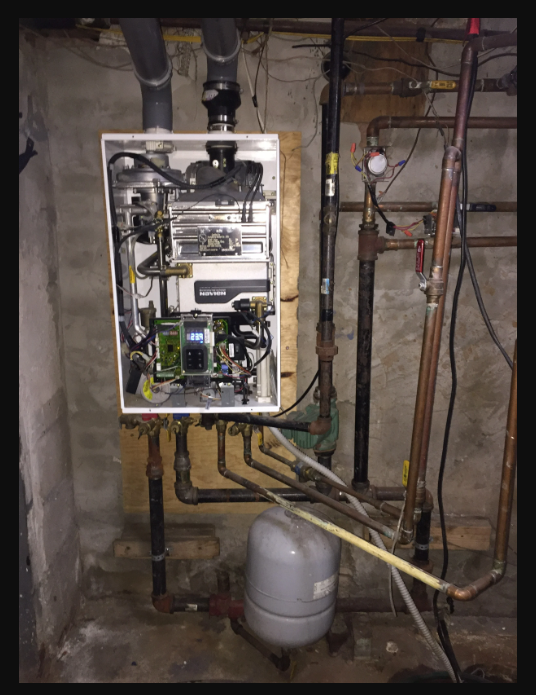

Navien Air Pressure Sensor Bypass; Instructions

This article will provide an overview of the Navien air pressure sensor bypass, a cost-effective solution for controlling air pressure in a home or office. The bypass allows you to make adjustments to the air pressure without having to replace the entire pressure sensor.

We will discuss the advantages and disadvantages of using this bypass, as well as provide instructions for installation and maintenance. Finally, we will cover some tips for troubleshooting any issues you may encounter.

Table of Contents

What does the Navien air pressure sensor do?

The Navien air pressure sensor measures the air pressure in a heating, ventilation, and air conditioning (HVAC) system. It aids in the detection of changes in air pressure, which are used to regulate the system and ensure that it is operating properly and efficiently.

The air pressure sensor aids in maintaining comfortable air temperatures and lowering energy costs. It also helps to ensure that the system is safe to use and free of any potential problems or dangerous conditions.

Navien air pressure sensor troubleshooting

- Check to make sure the air pressure sensor is properly connected to the Navien system. This includes ensuring all connections are secure and the wiring is correctly attached.

- Check the Navien system’s settings to make sure the air pressure sensor is enabled and the desired pressure is set correctly.

- Inspect the air pressure sensor for any signs of damage or wear.

- If the air pressure sensor is connected correctly and the settings are correct, reset the system.

- If the problem persists, check the air pressure reading on the pressure gauge. If it is not within the expected range, then the air pressure sensor may need to be replaced.

- If the air pressure sensor is still not working properly, contact a qualified technician to check the system and diagnose the issue.

Flammable Vapor Sensor Got Wet; What Should You Do?

sensor diary

Navien Error Codes

1. E001: This error code indicates an issue with the water flow sensor.

Check for any obstructions or blockages in the water pipes and the water flow sensor. Check to make sure the water flow rate is within the acceptable range. If the issue persists, contact a professional to inspect the water flow sensor.

2. E011: This error code indicates an issue with the gas pressure sensor.

- Check the gas pressure sensor to make sure it is properly connected and not damaged.

- Check the gas pressure at the inlet of the unit. If it is too low, adjust it to the recommended pressure as stated in the manual.

- Make sure there are no blockages or restrictions to the gas line.

- Check the flue pipe for any blockages or restrictions.

- If the problem persists, contact a qualified technician for further assistance.

3. E021: This error code indicates an issue with the combustion fan motor.

- Check the wiring of the combustion fan motor.

- Check the motor itself for any signs of damage or wear.

- Check that the motor is receiving the correct voltage.

- Replace the combustion fan motor if necessary.

4. E031: This error code indicates an issue with the ignition.

- Check that the gas line is turned on and the gas pressure is correct.

- Check if there is a spark at the ignition electrode.

- Check if the ignition electrode is properly installed and if it is not damaged.

- If there is a spark, check if the igniter is generating heat.

- Replace the ignition electrode if necessary.

5. E041: This error code indicates an issue with the flue gas temperature sensor.

The first step is to check if the flue gas temperature sensor is connected correctly and if it is within the normal operating range. If the sensor is not connected correctly, reconnect it and then reset the system. If the sensor is connected correctly, then replace it with a new one.

6. E051: This error code indicates an issue with the water temperature sensor.

- Check the water temperature sensor for any signs of corrosion or damage.

- Verify that the water temperature sensor is securely connected to the main board.

- Replace the water temperature sensor if necessary.

- Check the wiring for any loose connections or broken wires.

- Check the main board for any signs of damage or corrosion.

- Replace the main board if necessary.

- If the error code persists, contact a qualified service technician.

7. E061: This error code indicates an issue with the exhaust temperature sensor.

- Check for any blockages in the venting system.

- Make sure the venting system is properly connected and secured.

- Check the exhaust temperature sensor for any damage or corrosion.

- Clean the exhaust temperature sensor and reset the error code.

- If the error persists, replace the exhaust temperature sensor.

8. E071: This error code indicates an issue with the air pressure sensor.

- Check the pressure sensor is securely connected.

- Make sure the pressure sensor is not blocked or clogged.

- Check the air filter and replace it if necessary.

- Make sure all of the vent lines are clear and unobstructed.

- Check the pressure switch and replace it if necessary.

- Reset the boiler by turning off the power and then back on again.

9. E081: This error code indicates an issue with the exhaust pressure sensor.

This error code requires a technician to perform a diagnosis and repair. The technician will need to check the exhaust pressure sensor, wiring, and connections. In some cases, it may be necessary to replace the sensor.

10. E091: This error code indicates an issue with the water pressure switch.

- Check the water pressure switch and make sure it is securely connected to the water supply line.

- Check the air pressure hose connection and make sure it is securely connected to the pressure switch.

- Check the water pressure switch wiring and make sure it is connected properly.

- Check the air pressure hose for any signs of blockage, and clear it if necessary.

- If the error code persists, contact a qualified technician for further diagnosis and repair.

Air Lift Pressure Sensor Fault; Everything You Need To Know.

sensor diary

How to bypass the Navien Air Pressure Sensor?

Generelly, It is not possible to bypass the Navien Air Pressure Sensor. The sensor is designed to detect changes in air pressure and send a signal to the system to adjust accordingly. If the sensor is not working correctly, the system will not be able to adjust and the system may not work properly.

But if you still want to do it, then I recommend watching the following YouTube video to get a better understanding of how it is done.

How to clean Navien flow sensor?

- Shut off the power to the Navien flow sensor.

- Remove the cover from the Navien flow sensor.

- Unscrew the two screws that hold the flow sensor in place.

- Carefully remove the flow sensor from the Navien unit.

- Use a soft brush or cloth to remove any debris or dirt from the flow sensor.

- Use a soft, damp cloth to wipe down the flow sensor.

- Use a cotton swab dipped in alcohol to remove any stubborn dirt or debris from the flow sensor.

- Reinstall the flow sensor in the Navien unit and secure with the two screws.

- Replace the cover on the Navien flow sensor.

- Turn the power back on to the Navien flow sensor.

How to test Navien flow sensor?

- Begin by turning off the power to the flow sensor.

- Next, disconnect the two wires that are connected to the flow sensor.

- Use a multimeter to measure the resistance of the flow sensor. You should see a reading of approximately 0.2 ohms.

- Reconnect the wires to the sensor and turn the power back on.

- With the power on, open a hot water tap in the system.

- Slowly increase the flow of water until the flow sensor is triggered.

- Once the flow sensor is triggered, use a multimeter to measure the resistance of the flow sensor. The reading should now be approximately 0.5 ohms.

- If the readings are correct, the flow sensor is functioning properly.