7.3 Exhaust Back Pressure Sensor Symptoms: Warning Signs to Look Out For

The Exhaust Back Pressure (EBP) sensor is a critical component in the 7.3 engine found in certain Ford trucks and vans. This sensor measures the pressure of the exhaust gases leaving the engine, which helps to regulate the engine’s performance. However, when this sensor malfunctions, it can cause a variety of problems with the vehicle’s performance.

In this article, we will discuss common symptoms of a faulty EBP sensor in the 7.3 engine, how to diagnose the issue, and ways to repair and prevent EBP sensor failure.

Table of Contents

- What is an Exhaust Back Pressure Sensor in the 7.3 Engine?

- Common Symptoms of a Failed EBP Sensor in the 7.3 Engine

- Diagnosing a Faulty EBP Sensor

- Repairing a Faulty EBP Sensor in the 7.3 Engine

- Preventing EBP Sensor Failure in the 7.3 Engine

- 7.3 exhaust back pressure valve stuck closed; How to deal with it?

- 7.3 EBP sensor test; How it can be done DIY?

- Conclusion

- Some related FAQs

What is an Exhaust Back Pressure Sensor in the 7.3 Engine?

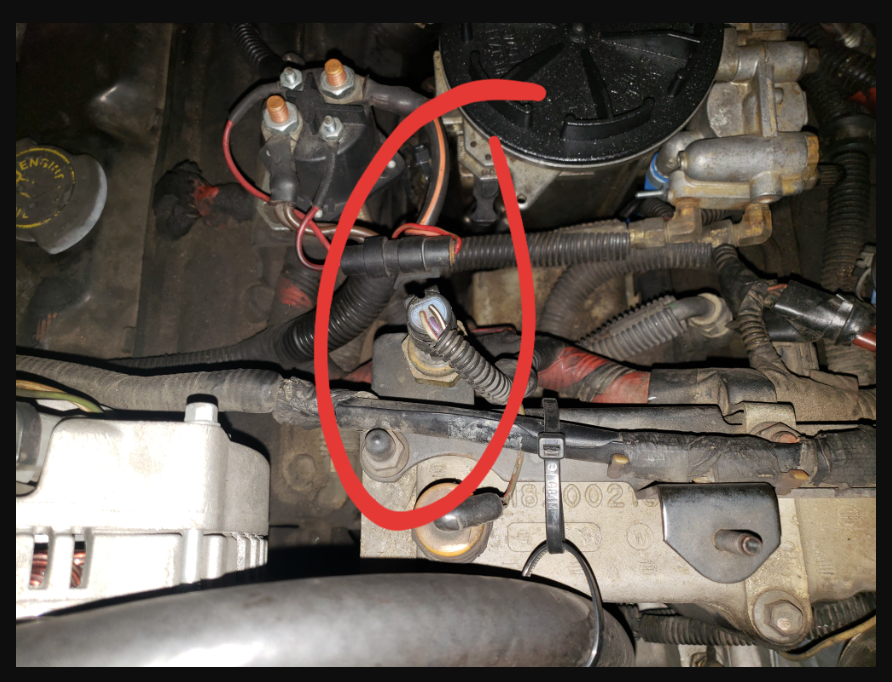

The Exhaust Back Pressure (EBP) sensor in the 7.3 engine is an electronic device that measures the pressure of the exhaust gases leaving the engine. It is typically located on the passenger side exhaust manifold.

The sensor sends a signal to the vehicle’s engine control module (ECM), which uses the data to regulate the engine’s performance. A faulty EBP sensor in the 7.3 engine can cause a variety of performance issues, including reduced power and acceleration, poor fuel efficiency, and engine misfires or stalling.

Common Symptoms of a Failed EBP Sensor in the 7.3 Engine

There are several warning signs that indicate a faulty EBP sensor in the 7.3 engine. These include:

Warning light on dashboard: If the Check Engine light on the dashboard comes on, it could be due to a faulty EBP sensor. The ECM will detect a problem with the EBP sensor and trigger the warning light.

Reduced power and acceleration: If the 7.3 engine experiences a loss of power or acceleration, it could be due to a faulty EBP sensor. The ECM may reduce engine power to prevent damage to the engine.

Poor fuel efficiency: A faulty EBP sensor can cause the 7.3 engine to run rich or lean, which can result in poor fuel efficiency.

Engine misfires or stalling: If the 7.3 engine misfires or stalls while driving, it could be due to a faulty EBP sensor. The ECM may not receive accurate data from the EBP sensor, causing the engine to misfire or stall.

Diagnosing a Faulty EBP Sensor

If you suspect that the EBP sensor in the 7.3 engine is faulty, you can diagnose the issue by:

Using an OBD-II scanner: You can use an OBD-II scanner to read the error codes stored in the ECM. If the scanner detects an error code related to the EBP sensor, it could indicate a faulty sensor.

Testing the sensor with a multimeter: You can test the EBP sensor in the 7.3 engine with a multimeter to measure the voltage output. A faulty sensor may produce an inconsistent voltage output.

Inspecting wiring and connections: You can inspect the wiring and connections to the EBP sensor in the 7.3 engine for damage or corrosion. Damaged wiring or connections can cause the sensor to malfunction.

Repairing a Faulty EBP Sensor in the 7.3 Engine

If the EBP sensor in the 7.3 engine is faulty, you can repair the issue by:

Replacing the sensor: You can replace the faulty EBP sensor in the 7.3 engine with a new one. Be sure to purchase a sensor that is compatible with your vehicle’s make and model.

Cleaning the sensor: You can clean the EBP sensor in the 7.3 engine with a sensor cleaner to remove any debris or buildup. This can sometimes fix the issue

Repairing wiring and connections: You can repair any damaged or corroded wiring or connections to the EBP sensor in the 7.3 engine. This can often fix the issue and prevent future sensor failure.

Preventing EBP Sensor Failure in the 7.3 Engine

To prevent EBP sensor failure in the 7.3 engine, you can take the following steps:

Perform regular maintenance: Regular maintenance, such as oil changes and tune-ups, can help keep the engine running smoothly and prevent sensor failure.

Avoid harsh driving: Avoid harsh driving, such as excessive idling, overloading the vehicle, and harsh acceleration, which can all contribute to premature sensor failure.

Address warning signs promptly: If you notice any warning signs of a faulty EBP sensor in the 7.3 engine, such as a Check Engine light or reduced power, address the issue promptly to prevent further damage.

7.3 exhaust back pressure valve stuck closed; How to deal with it?

When the EBP valve in the 7.3 engine is stuck closed, it restricts the flow of exhaust gases and can cause a reduction in engine power and acceleration. This can also cause the engine to consume more fuel than usual and potentially misfire or stall altogether.

To fix a stuck-closed EBP valve in the 7.3 engine, the valve must be inspected to determine the cause of the issue. Often, the valve may simply be stuck due to the build-up of carbon or other debris in the valve’s internal components. In this case, cleaning the valve or replacing it entirely can resolve the issue.

If the EBP valve is stuck closed due to an electrical issue, such as a faulty sensor or wiring issue, these components will need to be inspected and repaired or replaced as necessary. It’s important to note that in some cases, the EBP valve may not be the root cause of the issue, and further diagnosis may be required to determine the underlying problem.

7.3 EBP sensor test; How it can be done DIY?

Testing the Exhaust Back Pressure (EBP) sensor in the 7.3 engine can help diagnose any issues with the sensor and prevent further damage to the engine.

Tools Required

To test the EBP sensor in the 7.3 engine, you will need the following tools:

- OBD-II scanner

- Multimeter

- Pen and paper

Steps for Testing the EBP Sensor in the 7.3 Engine

Step 1: Connect OBD-II Scanner

Connect an OBD-II scanner to the vehicle’s diagnostic port, typically located under the dashboard on the driver’s side. Turn on the scanner and select “Read Codes” to check for any codes related to the EBP sensor.

Step 2: Check EBP Sensor Wiring

Inspect the wiring and connections to the EBP sensor. Look for any signs of damage or corrosion, and ensure that all connections are clean and tight. If there are any issues with the wiring or connections, repair or replace as necessary.

Step 3: Test EBP Sensor with Multimeter

Disconnect the EBP sensor from the engine and use a multimeter to test the sensor’s resistance. Set the multimeter to the Ohms setting and touch the probes to the two terminals on the sensor.

The multimeter should read between 0.5 and 1.5 Ohms of resistance. If the resistance is outside of this range, the sensor may be faulty and require replacement.

Step 4: Test EBP Sensor Voltage

Reconnect the EBP sensor and turn on the engine. Use the multimeter to test the voltage output of the EBP sensor. Touch the multimeter probes to the sensor’s two terminals and record the voltage reading.

The voltage should increase as the engine RPMs increase. If the voltage reading is outside of the normal range, the sensor may be faulty and require replacement.

Step 5: Interpret Test Results

Compare the results of the EBP sensor tests to the manufacturer’s specifications. If the results fall outside of the recommended range, the sensor may be faulty and require replacement.

If the sensor tests within the recommended range but there are still issues with the engine’s performance, further diagnosis may be necessary to determine the root cause of the issue.

Infiniti Q50 Front Sensor Malfunction Explained; By Sensor Guides

sensor Diary

Conclusion

The Exhaust Back Pressure (EBP) sensor in the 7.3 engine is a critical component that regulates the engine’s performance by measuring the pressure of the exhaust gases leaving the engine. A faulty EBP sensor in the 7.3 engine can cause a variety of performance issues, including reduced power and acceleration, poor fuel efficiency, and engine misfires or stalling.

To diagnose a faulty EBP sensor in the 7.3 engine, use an OBD-II scanner, test the sensor with a multimeter, or inspect wiring and connections. If the sensor is faulty, you can replace it, clean it, or repair wiring and connections. To prevent EBP sensor failure in the 7.3 engine, perform regular maintenance, avoid harsh driving, and address warning signs promptly. By taking these steps, you can keep your 7.3 engine running smoothly and prevent costly repairs down the road.

Pre-Collision System Unavailable Clean Sensor: Everything You Need to Know

sensor diary

Some related FAQs

Can I drive without an exhaust sensor?

It is not recommended to drive without an exhaust sensor. The sensor plays an important role in monitoring and regulating the emissions of your vehicle, and without it, your engine may not perform optimally and can cause damage to other parts of your vehicle.

Additionally, driving without an exhaust sensor may cause your vehicle to fail emissions tests and potentially violate local regulations.

Can back pressure damage an engine?

Back pressure levels that are too high can impair engine performance and increase fuel consumption as well as emissions.